Tracking Down Microplastics

Published on by Water Network Research, Official research team of The Water Network in Science

Daniel Venghaus is engaged in research at the TU Berlin in the field of urban water management, where he works on avoidance strategies to prevent microplastics from entering aquatic systems.

In a discussion here, he explains the objectives and details of some initial successes.

In a discussion here, he explains the objectives and details of some initial successes.

What is the significance of microplastics in the field of urban water management?

According to a recent literature study, as much as 2.5 million tonnes of microplastics could find their way into aquatic systems per year. Some 25% of these microplastics enter circulation via the outlet of sewage plants, while 66 percent take the form of street runoff water.

Why is this the case?

Processes used to date are not specifically designed to filter microplastics at the outlet of sewage plants or street runoff water. The various volumes of microplastics in municipal wastewater have scarcely been researched to date.

The Sampling Basket is Hung in Drains and Facilitates Reliable Sampling of All Street Runoff Water

Among others, the TU Berlin is addressing this topic intensively in two projects sponsored by the Federal Ministry of Education and Research. These projects are referred to as OEMP and RAU. What are the objectives of these projects?

The goal with OEMP is to develop innovative materials and processes to improve the retention of microplastic particles of the various size, shape, or material characteristics during municipal wastewater treatment.

The collaborative research project entitled Tire abrasion in the environment (RAU) examines the emergence, composition, and retention of tire abrasion throughout the entire useful life of a tire. The goal here is to balance its quantities, as well as to both identify and quantify the influential factors and paths leading to its occurrence as a way of highlighting options for its reduction.

The technical weavers GKD – Gebr. Kufferath AG were a project partner in both projects. How did the partnership come about and what were GKD’s main duties in this regard?

When we started taking initial samples in 2013, the key was to find a filter material that could deliver the strict separation limit of 10 micrometers, while also securing the requisite flow rate. It also needed to be rugged, since acids, alkalis, and enzymes may need to be blasted against the filter cake on the mesh to ensure that the particulate material is removed along with the microplastics.

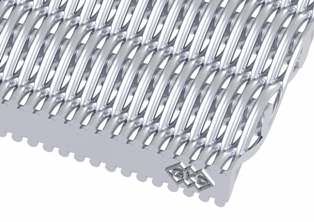

With its Optimized Dutch Weaves (ODW), GKD already offered one such filter material. The company further refined this mesh in the course of the OEMP project, so that ODW is now also available with separating limits of 8 and 6 micrometers. Assuming a good flow rate, the volume of retained particles at the sewage plant outlet is approximately double with ODW 6 in comparison with ODW 20.

This is just one of several reasons why this high-performance mesh is also being used in the RAU project. The most important point, however, is that not only the product but also the partner company is highly innovative. In our experience, GKD is committed to developing mesh for a very wide range of applications and is not afraid of adopting a different perspective to develop new fields of application.

This is a real help, particularly in cases such as these where it is important for the partner to understand the objective and provide the right tools for the job. During the RAU project, the company was therefore tasked with developing a sampling basket with defined fractionation for sampling an entire rainfall event. This has already delivered excellent results.

GKD Developed a Sampling Basket with up to Six Filter Elements and Defined Fractionation for Sampling an Entire Rainfall Event

OK, let’s return to the OEMP and the optimized dutch weaves. What makes the product stand out?

The key advantage of this mesh over other filter media is its sharp separation limit. Within the scope of the OEMP project, we compared optimized weaves in a disc filter system with a cloth filter in a drum filter system. The drainage values were similar for both configurations. The aperture of the optimized dutch weaves is an absolute value, enabling the system operator to guarantee that no spherical particles larger than 6 micrometers could find their way into the water.

GKD Developed a Sampling Basket with up to Six Filter Elements and Defined Fractionation for Sampling an Entire Rainfall Event

The same mesh is also used for the RAU project in a sampling basket. How does this sampling basket work?

An integrated filter cascade is used to catch the tire particles from the street runoff drains. The sampling basket separates all particulate material that is larger than 6 micrometers. While engaged in this research project, we are interested both in the entire mass of tire abrasion and the respective quantity of this in a fraction, so that we can estimate which contains the greatest volume of abrasion.

Depending on the area, the sampling basket employs up to six filter elements, which can best be envisaged like sieve pans. To be able to use the basket in any street, we took the leaf grate used in many drains as our inspiration and GKD developed a basket with similar dimensions. This basket can be used in all locations and for the first time facilitates reliable sampling of all street runoff water. Until now, it had only been possible to sample partial flow.

We can also use the basket to sample various rainfall events – from very heavy rain to very light rain. The latter was not possible at all in the past. Another advantage of the basket is the integrated online measurement functionality, which measures street runoff from the very first second without the warm-up time of conventional measuring technology.

For the first time, this has also enabled us to automatically sample the so-called first flush – i.e. the rain that feeds the drains in the first few minutes and is the subject of much discussion in the field of research – and evaluate this based on the respective drainage basin. This performance spectrum makes the sampling basket a core element of the RAU project.

Where exactly is this basket used within the scope of the RAU project?

First of all, its functionality was verified in comprehensive laboratory testing. For the in-situ sampling now following, we chose the deployment locations on the basis of load scenarios: main streets and side streets, highway ramps, parking spaces, traffic lights, roundabouts, etc. as well as various road surfaces. We hope that this will provide us with valid findings as to how tire abrasion even occurs, the size of the particles, what they look like, and the density of the abrasion…

The Optimized Dutch Weaves from GKD Secure a Strict Separation Limit up to Six mm with a High Requisite Flow Rate

What is the significance of the sampling basket from the perspective of urban water management?

It is an important instrument that should help in developing ideas and approaches to the factors to be determined within the scope of the RAU project. With the sampling basket, we are capable of filtering out all particulate materials in street runoff down to a size of 6 micrometers for subsequent analysis.

Going beyond sampling, we will also investigate the filter potential as a localized cleaning system for the basket. It is important to understand here that street runoff is often dewatered via wastewater separation channels and can then make its way into rivers without first being treated. When using mixed sewage systems, on the other hand, it is forwarded to the sewage treatment plant.

Thanks to the fractioned sampling, we can investigate individual rainfall events to describe and evaluate tire abrasion. The ultrafine separation limit of the optimized dutch weaves permits sampling down to the fine particulate size, which starts at 10 micrometers. With this sampling, we are keen to evaluate drainage basins, understand challenges, and derive solutions.

What was GKD’s special contribution in the product developments you have mentioned?

The optimized dutch weave opens up a broad range of applications. For example, we have used it to filter various sewage plant outlets and mixed sewage during the OEMP project. In the RAU project, it has also been used to construct a sampling device. These are very different things, as the requirements of a sampling device are quite different than those of a filter system.

The basket is a prime example of innovative implementation of an equally innovative mesh as a scientific response to a concrete application/issue. The scientist defines the requirements and the company provides the technical solution. This makes GKD an eye-level sparring partner.

The Optimized Dutch Weaves from GKD Secure a Strict Separation Limit up to Six mm with a High Requisite Flow Rate

What are the next planned steps?

Within the scope of OEMP, mixed sewage investigations are currently being performed, during which we apply this exacting wastewater type to the systems. To this end, we connected filter systems to a mixed sewage basin operated by Berliner Wasserbetriebe. In the RAU project, the in-situ street runoff water sampling process is getting underway. Sixty such processes are planned over the course of the next two years.

Source: Express Water

Media

Taxonomy

- Micropollutants

- Polymers & Plastics

- plastic pollution

- plastic debris

- microplastics